Polypropylene (PP) is a thermoplastic polymer made from the monomer propylene. This material .has a wide range of applications in various industries due to its unique properties

Characteristics and properties of polypropylene

– High thermal resistance: Polypropylene can withstand high temperatures and is resistant to melting.

– Chemical resistance: This polymer is resistant to many chemicals such as acids and bases.

– Light weight: One of the main advantages of polypropylene is its low weight, which reduces transportation costs and use in various industries.

– Recyclability: Polypropylene is a recyclable polymer, which makes it a suitable option for producing sustainable products.

Applications of polypropylene

– Packaging industry: Used in the production of films, sheets and food packaging containers.

– Automotive industry: Manufacture of automotive parts such as bumpers and dashboards.

– Textile industry: production of carpets and abrasion-resistant fabrics.

– Medical equipment: used in the production of syringes, test tubes and other disposable medical instruments.

– Household appliances: manufacturing food storage containers, toys and kitchen utensils.

Polypropylene production process

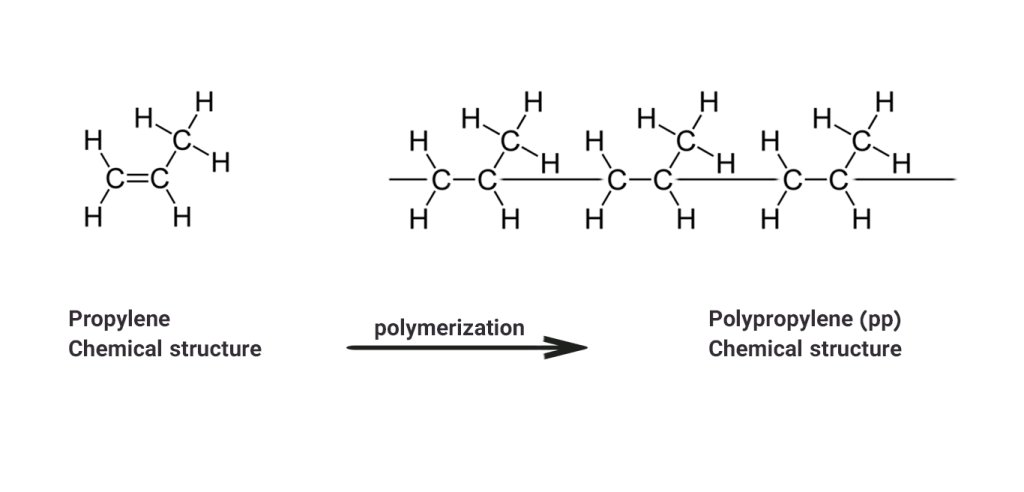

Polypropylene is produced through the polymerization process of propylene monomer. This process is usually carried out using Ziegler-Natta or metallocene catalysts that help regulate the structure and properties of the polymer.

Types of polypropylene

– Polypropylene homopolymer (PP-H): has a semi-crystalline and solid structure, suitable for packaging, textiles and automotive industries.

– Polypropylene copolymer (PP-C): contains other monomers such as ethene, which is divided into two groups: random (PP-R) and block (PP-B).

How polypropylene is formed:

Here is a complete specification table for Polypropylene:

| Property | Specification |

|---|---|

| Chemical Formula | (C3H6)n |

| Density | 0.9 g/cm³ |

| Melting Point | 160-170°C |

| Flash Point | 260°C |

| Chemical Resistance | Resistant to acids and bases |

| Thermal Resistance | Up to 100°C without deformation |

| Flexibility | Moderate |

| Tensile Strength | 30-35 MPa |

| Applications | Packaging, automotive, medical equipment, piping |

| Recyclability | Yes |